Original paper is published by-

K. Banerjee and N. Srivastava, University of California

Summarised by Anant B. Marahatta

What is VLSI?

• Very-large-scale integration (VLSI) is the process of creating integrated circuits by combining thousands of transistor-based circuits into a single chip.

• VLSI began in the 1970s when complex semiconductor and communication technologies were being developed. The microprocessor is a VLSI device.

New wiring solutions…!

• Metallic carbon nanotubes (CNTs) are promising candidates that can potentially address the challenges faced by copper and thereby extend the lifetime of electrical interconnects.

• carbon nanotubes (CNTs) have aroused a tremendous amount of interest in their use as building blocks of future integrated circuits due to their outstanding electrical properties

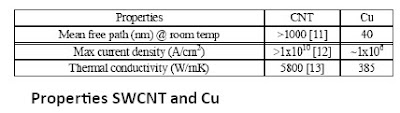

CNT based interconnects can potentially offer significant advantages over copper.

• CNTs exhibit extraordinary strength and unique electrical properties are efficient conductors of heat and are metallic in nature.

•SWCNTs are a very important variety of CNT because they exhibit important electric properties that are not shared by MWCNTs. The remarkable properties of SWCNTs stem from the symmetry and unusual electronic structure of grapheme [one atom thick sheet of graphite].

Reliability and Thermal Analysis

However, the need to reduce interconnect resistance (and hence delay) makes it necessary to pack several thousands of CNTs in a bundle.

Conclusion

K. Banerjee and N. Srivastava, University of California

Summarised by Anant B. Marahatta

What is VLSI?

• Very-large-scale integration (VLSI) is the process of creating integrated circuits by combining thousands of transistor-based circuits into a single chip.

• VLSI began in the 1970s when complex semiconductor and communication technologies were being developed. The microprocessor is a VLSI device.

New wiring solutions…!

• Metallic carbon nanotubes (CNTs) are promising candidates that can potentially address the challenges faced by copper and thereby extend the lifetime of electrical interconnects.

• carbon nanotubes (CNTs) have aroused a tremendous amount of interest in their use as building blocks of future integrated circuits due to their outstanding electrical properties

CNT based interconnects can potentially offer significant advantages over copper.

• CNTs exhibit extraordinary strength and unique electrical properties are efficient conductors of heat and are metallic in nature.

•SWCNTs are a very important variety of CNT because they exhibit important electric properties that are not shared by MWCNTs. The remarkable properties of SWCNTs stem from the symmetry and unusual electronic structure of grapheme [one atom thick sheet of graphite].

∙An isolated CNT can carry current densities in excess of 1010 A/cm2 without any signs of damage even at an elevated temperature of 250 0C. However, the high resistance associated with an isolated CNT (greater than 6.45 KΩ) necessitates the use of a bundle (rope) of CNTs conducting current in parallel to form an interconnection. CNT bundle interconnects have superior performance compared to Cu.

∙For short CNT bundle with small length (L), [especially for L < λCNT], resistance is higher than that of a Cu interconnect because the large contact resistance dominates the overall CNT resistance. However, for long interconnect lengths; i.e. long CNT bundle interconnects have smaller resistance than their Cu counterparts [ L>λCNT].

∙The interconnect delay can be reduced considerably by using densely packed CNT bundle interconnects, so that large power savings can be achieved. CNT bundle interconnects can reduce intermediate level interconnect delay by more than 60% due to their lower resistance.

Reliability and Thermal Analysis

∙Due to strong sp2 bonding, carbon nanotubes are much less susceptible to electro-migration (EM) problems [that plague copper interconnects] and can carry very high current densities. Metallic single-walled CNT bundles have been shown to be able to carry extremely high current densities of the order of 109 A/cm2. Cu interconnects = 106 A/cm2 due to EM.

∙A 100 x 50 nm2 cross-section Cu interconnect can carry current up to 50 μA, whereas a 1 nm diameter CNT can carry upto 20-25 uA current. Hence, from a reliability perspective, a few CNTs are enough to match the current carrying capacity of a typical Cu interconnect.

Conclusion

∙There is no any experimental work or theoretical analysis yet about the nature of electromagnetic interactions between non-isolated (or tangled) nanotubes. So the authors have not considered their mutual effect during conduction, however they highlighted that this challengeable investigation should be done before using them in a circuit though these challenges are not expected to cause any fundamental problems.

No comments:

Post a Comment